Maglev Technology

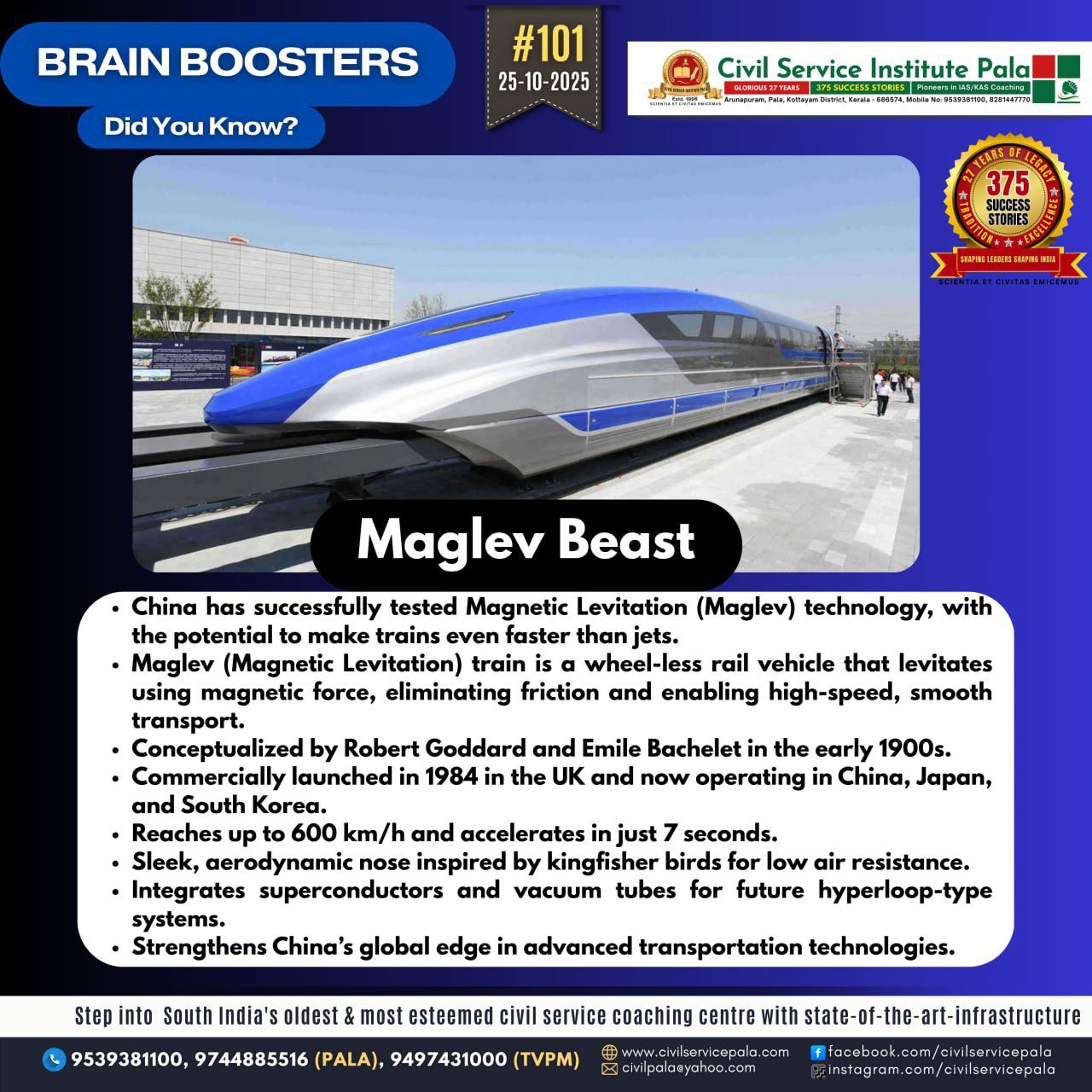

Maglev Technology (Magnetic Levitation Technology) Meaning: “Maglev” stands for Magnetic Levitation, a transport technology that uses magnetic forces to lift, propel, and guide vehicles — mainly trains — without physical contact with the tracks.

Working Principle: It is based on electromagnetic suspension or electrodynamic suspension systems that create lift and thrust using magnetic fields.

No Friction: Since the train floats above the guideway, there is no contact, resulting in minimal friction and very high speeds.

Components: Magnets (electromagnets or superconducting magnets) Guideway/Track (contains coils for magnetic reaction) Propulsion system (linear motor for movement)

Types of Maglev Systems: Electromagnetic Suspension (EMS): Uses electromagnets on the train to attract it to the steel track (used in Germany).

Electrodynamic Suspension (EDS): Uses superconducting magnets that repel the guideway to levitate (used in Japan). Advantages: Extremely high speed (up to 600 km/h) Low noise and vibration Low maintenance (no wheel or track wear)

Energy-efficient at high speeds Disadvantages: High construction cost Requires special tracks (not compatible with conventional rail) High energy use during start-up Maglev Trains Definition: Trains that operate using magnetic levitation instead of traditional wheels on rails.

Key Examples: Japan’s SCMaglev: World’s fastest train (tested speed ~603 km/h).

Shanghai Maglev: Commercially operates between Pudong Airport and Longyang Road, speed ~431 km/h.

Transrapid (Germany): Developed for high-speed intercity travel. Operation: The train is levitated by magnetic repulsion. Linear motors push the train forward using electromagnetic forces. The train is guided by side magnets to stay centered on the track.

Environmental Impact: Produces less air and noise pollution, making it eco-friendly for future transport systems.

Future Potential: Promising technology for ultra-high-speed, low-maintenance, and sustainable transportation networks.